Spring Properties

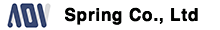

Aoi Spring uses wire forming machines to bend wires into a variety of shapes.

Compared to springs pressed with a stamping die, wire formed springs offer the following advantages:

1. No upfront investment. (However, there are special cases when costs for jigs and other tools may arise.)

2. You can change designs quickly.

3. Less material loss means wire forming is the best way to cut costs.

Aoi Spring can fulfill your requests with our vast array of wire forming machines.

Hairpin wire forming

Application: Automotive parts

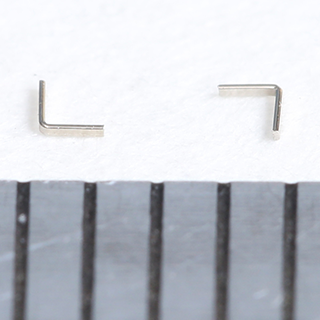

Ultra-small wire forming

Materials: Pure nickel

Thickness: 0.1 × 0.2mm

Applications: Lithium-ion batteries, nickel particles for forced internal short circuit testing

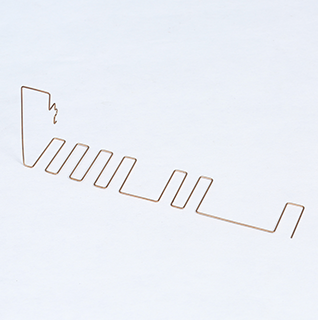

34 bending process antenna

Materials: C5210W-H

Wire diameter: Φ0.8mm

Application: Signal receiver parts

Wire forming with small D/d Index

Materials: SUS304-WPB

Wire diameter: Φ3.0mm

Application: Bottle cap stopper

Complex wire forming (horizontal length: 200mm)

Materials: SWM-B

Wire diameter: Φ3.2mm

Application: Agricultural machine parts

Complex wire forming (80mm × 150mm)

Materials: SUS304-W2

Wire diameter: Φ3.0mm

Application: Air conditioning outdoor unit parts

Notable Achievements

Compatible Diameters

φ 0.2 mm – φ 7.0 mm

Materials Track Record

| SUS304-WPB | SUS304-WPA | SUS304W1 |

| SUS304W2 | SUS316 (chemical-resistant) | SUS631 (precipitation hardening) |

| plated wire | Hastelloy (chemical-resistant) | plated wire titanium |

| Hastelloy (chemical-resistant) | Inconel (for heat resistance) | SW-B |

| SW-C | SWP-A | SWP-B |

| SWRM-B | zinc | nickel |

| pure nickel | 7TN | phosphor bronze |

| beryllium copper | oxygen-free copper | brass |

| aluminum | titanium |

Applications

Equipment

surface treatment jig components

Light electric appliances

current-carrying components

Medical

electric pump components

What Makes Aoi Spring Special

* With 24 state-of-the-art NC spring forming machines, Aoi Spring can handle highly challenging projects while meeting tight delivery deadlines.

* In some cases, we have even delivered a finished piece to a customer the day after receiving a drawing or sample.

* Since we can also fabricate with special materials, Aoi Spring can handle material qualities suited to the environment intended for use. We look forward to hearing from you.